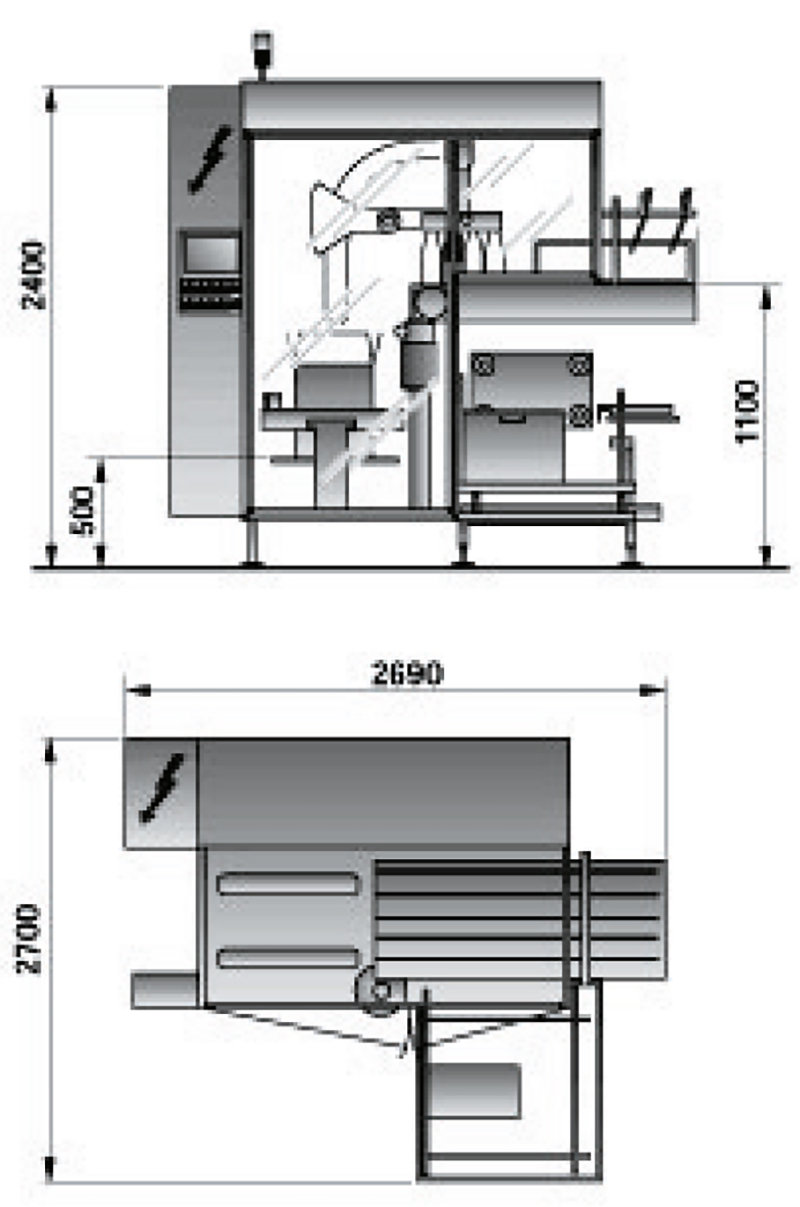

MBL 200

The machine Mod. M.B.L. 200 is an integrated packaging system which, in very reduced spaces, allows the moulding and filling operations in American cases of products such as bottles, small bottles, jars, pasta trays, etc. in the varoius different arrangements, configurations and layers possible. The cases embrasure can be either positive or by contrast.

The grip head support arm can be fitted with a rotary device to allow the introduction of the product turned 90° or 180° of the running direction. The cases lower flaps are closed with hot-melt glue, or simply folded in order to be taped above and below once out of the machine. This machine is extremely compact and reliable. Its simplicity allows a large access to the working area and very limited maintenance costs. The machine can be carried out with either right or left work direction.

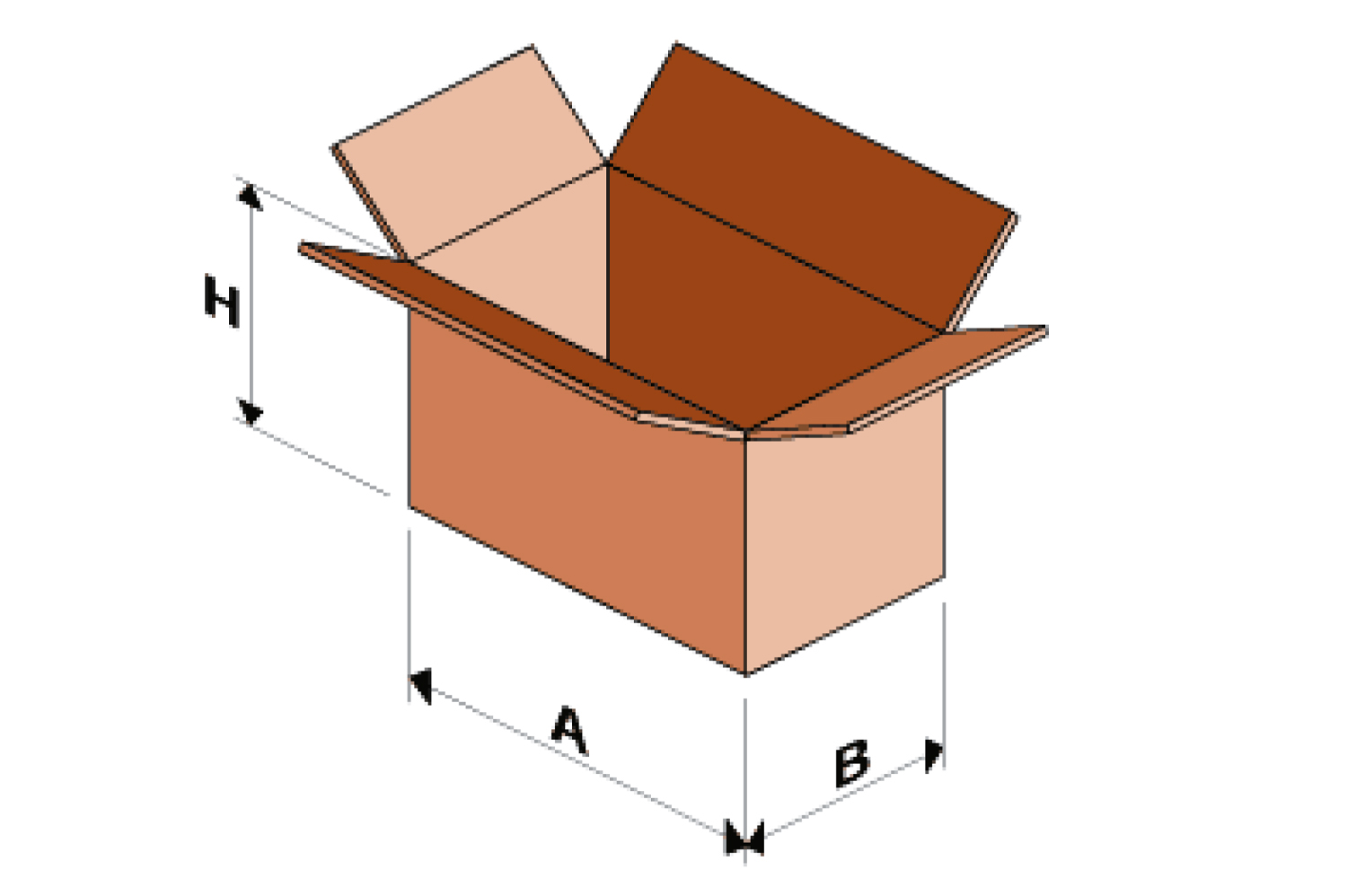

CASE SIZE

A (mm.): min. 200 max 500

B (mm.): min. 150 max 450

H (mm.): min. 150 max 420

INFO & CONTACTS

CASE SIZE

A (mm.): min. 200 max 500

B (mm.): min. 150 max 450

H (mm.): min. 150 max 420